|

A common trigger of the need to develop new products is a change in the legislative landscape. This was the challenge faced by RFD in 2008 with the release of the Australian Standard for Personal Flotation Devices AS 4758 to replace the 4 different Australian Standards in place at the time.

Changes in legislation for all the Australian States and Territories followed with appropriate lead times for manufacturers and suppliers to replace their ranges with compliant products.

As a safety critical product, personal floatation device performance is mandated by legislation and is subject to increasingly demanding requirements for performance, labelling, testing and even terminologies. In the old days, we called these things Life Jackets, but have forsaken this description so that people understand that these devices can’t save lives but can only aid in the preservation of life.

It is no surprise then that the new standard required additional buoyancy performance for the different use scenarios.

RFD had some years ago abandoned their design control over their PFD products, shut down their local manufacturing facility and had brokered supply arrangements with other manufacturers for their range. To coincide with the new standards, RFD decided to take back the design control of their PFD products and to manufacture the products themselves in facilities part owned by their parent company, Survitec, in China.

This project was a significant investment by RFD in re-establishing the technologies and knowledge in the design and manufacture PFD’s for the Australasian market. Bayly was selected as RFD’s design partner to work with them through the process.

Initially we started with defining the different ranges of jackets that were required for RFD, selecting size ranges and making an important decision to be the first Australian company to invest in the design of devices specifically to fit female customers.

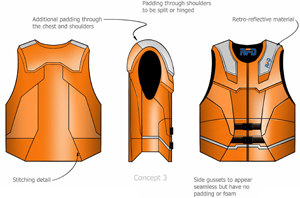

The designs of the jackets across the ranges needed to project a uniformity of key design attributes and common elements that reinforce their belonging to the RFD brand.

RFD required different ranges that would allow it to offer a premium product range as well as be able to compete at lower priced ranges using lower performance materials and reduced features. Through the selection of different materials, features and manufacturing details, RFD are able offer differently priced products to the market; providing a greater range of choice to the consumer.

Bayly worked with the RFD teams in Australia, New Zealand, Northern Ireland and China to realize 10 new life jacket ranges of inherently buoyant and inflatable jackets to the updated requirements of AS 4758.

Bayly worked on the design and development, detail design and CAD modeling and prototyping to produce patterns, assembly drawings and complete BOM specifications for up to 9 different sizes in each range using in-house, RFD local and Chinese manufacturing resources.

The complete specifications for the jackets were managed using Bayly's product lifecycle management (PLM) system. In all, 1185 different assembly and unique parts are defined across the PFD range. This is the largest project Bayly have ever attempted in terms of the shear number of different parts and BOMs and it would have proven impossible to control without a PLM solution.

Extensive use of Bayly's collaboration systems were required to facilitate communication between the team members.

|

|

|